Industrial racking refer to storage equipment dedicated to industrial enterprises. Different from the ordinary racking form, the industrial racking has developed into a modern storage device with a unique form and function. Industrial racking are the basis for the scientific storage and rapid transfer of enterprise products. The continuous innovation and development of racking and modern mechanical storage and transportation equipment technology has excellently met the high requirements of enterprises on the logistics chain. Its structure and design layout will bring scientific inventory management and direct benefit improvement to the enterprise. It is a point of profit growth that cannot be ignored, and this theory has been widely accepted.

We're here to help: Easy ways to get the answers you need.

Industrial racking system is a kind of low-cost investment, and its income is more profitable for enterprises, and it plays a huge role in income. In other words, it is not a wrong choice to install industrial racking in a warehouse and obtain the required space quickly and easily at low cost.

The obvious advantage of industrial racking lies in the space savings. They are specially designed so that companies can use all available space and save floor space. Industrial racking are placed side by side with each other, which can store more items and reduce space consumption. Make sure that there is no better opportunity to save space.

Since industrial racking are made of high-quality materials, they can provide good security. By effectively storing and organizing goods, industrial racking reduce the risk of accidents in the workplace. All racking systems have undergone extensive testing to ensure that they can withstand the expected weight. Please note that the dimensions of industrial racking are different, so the load-bearing capacity is also different.

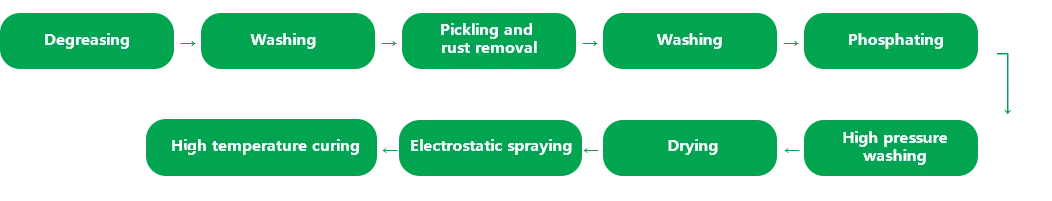

Surface treatment:

Using epoxy resin electrostatic spray treatment, the coating thickness is 60~80 microns;

Use a clean rag to remove the dust on the racking. Keep in mind that it is best to avoid clean water when cleaning the racking, because washing the racking with water can easily cause the surface of the racking to oxidize and shorten the racking life.

2. The racking are neatly arranged

Put the tools, accessories, and workpieces (products) stored on the racking neatly, and the pipes and lines must not be stacked to block the passage.

3. Special maintenance for special weather

Such as the maintenance method of the racking in wet days:

(1) Check the usage of the racking and follow the principle of racking usage

(3) Check the deformation of the racking;

(4) Check whether the beam and accessories are damaged, and correct the straightness of the column;

(5) Check the weight of the pallet cargo;

(6) Check whether the ground expansion bolts of the fixed column are loose;

(7) Check foot protection and other protective measures;

(8) Check whether the ground is sinking or damaged;

(9) The inspector should record truthfully according to the actual situation, and submit the written inspection result to the person in charge of the department, and dispatch professional racking personnel to eliminate hidden dangers.